|

| |

Got problems

with wrinkles, tears or improper work hardening

in draw and form operations?

The application

below can monitor key characteristics of these processes during the hit and

provide process verification on every part. These are very advanced

systems using much of the SAMview software family for accomplishing the

task. In-die force sensors are a must for meeting todays quality

standards. However, the illustrations below use press connection mounted

strainlinks and work well for process analysis.

Using the Signature Technologies SA-2000 Statistical Analysis Module

(SAM),

SAMview software

with the

SPCview/FeatureView

and the exclusive Patented Ford Features.

Signature

Technologies has cooperatively developed with Ford

Motor Company a means of determining percentage variation of material

thickness away from nominal IN CASES where a free stretch draw is made by

measuring the force during the draw and post-processing the data with

algorithms developed and patented by Ford Motor Company.

In practice, one ST feature

called "Ratio" is taken at the beginning of the draw process, and

another "Ratio" feature is obtained later in the draw, well up the

force slope. ST

processes are used to eliminate the draw ring backpressure so that only the

draw forces are considered.

The system works by post processing the returns from the

"Ratio" features with the patented Ford algorithm to discern changes

in the amplitude, and the slope of the signature.

|

|

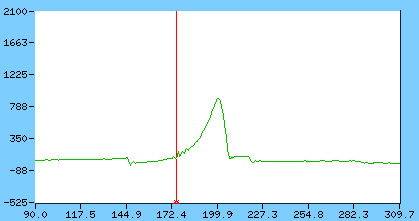

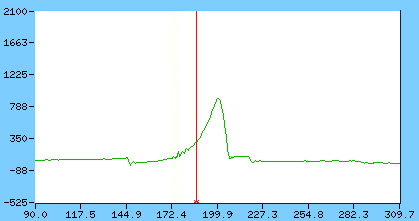

| The feature screens are shown in the screen

shots to the right.

These illustrate how the features are extracted from the signatures which

later are used in the calculations performed.

Note the placement of the Ratio Features, red vertical lines,

on

the forming slope. |

|

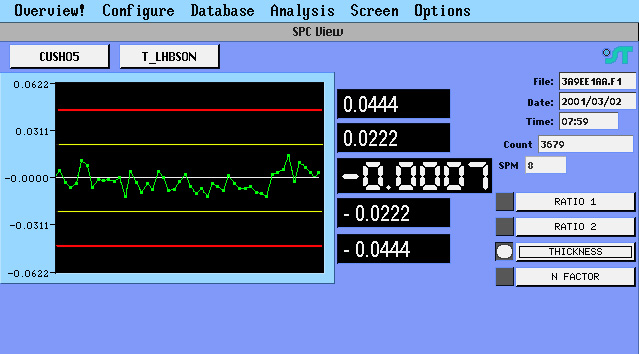

The screen

capture to the right shows variations of stock

thickness in fractions of a percent from nominal on every panel. Selection of N Factor would provide another

critical material property. Display

shows the quality and control limits of the process and displays the measured

values.

|

|

The SAM™ module can handle measurement inputs in

groups of 8 up to 56 total points

Signature Technologies can supply a wide variety of solutions to various manufacturing process

problems dealing with measurement, verification of properties, tool condition,

and machine health. We can also “close

the loop” by performing process adjustments in response to specific variations

in force, location, or shape of the work piece, as well as more simple controls

which can track and reject specific parts which don’t meet specific quality

criteria.

For a .pdf file copy of this bulletin please click here.

|